Knott Laboratory provides forensic engineering and animation, Civil & Structural, and Fire & Explosion Investigation services to reconstruct accidents.

What Fails in Applicance Water Solenoid Valves?

Failure modes include degradation, fractures or stress cracking

Published: June 28, 2019

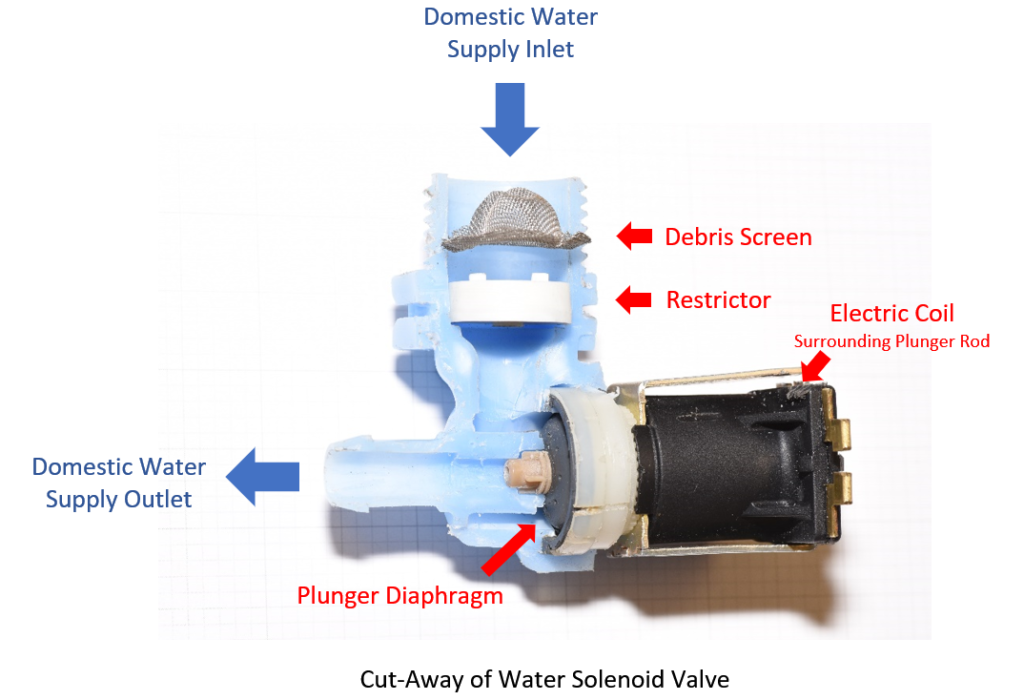

Water solenoid valves are common in everyday life and are frequently found in residential appliance applications. They are the point-of-connection between the domestic water supply and dishwashers, washing machines, dryers (with steam function), refrigerators, and ice makers. These components are electronically controlled by a switch or automated circuit to start and stop the flow of water. They are often unseen and unnoticed – until a water loss.

When attached to the domestic water supply, the inlet and plunger housings are constantly subjected to water pressure. This value is typically between 20 and 80 pounds per square inch gauge (PSIG), however spikes may be experienced as a result of the water supply regulation and/or design. Over time, modes of failure leading to a water loss may include degradation of the polymer components due to chemical attack, fracture due to over pressurization or environmental stress cracking (ESC), or mechanical wear resulting in an open or damaged plunger tip, diaphragm, or spring.

Each failure mode can manifest as a water loss in a different way. A fractured housing will result in an uncontrolled water escape from the valve to the interior and/or exterior of the appliance. An open or damaged plunger will result in uncontrolled water being delivered to the appliance, which may cause a subsequent overflow event. The volume of water lost will depend on the characteristics of the failure and the time needed to recognize the failure and shutoff the domestic water supply to the failed valve.

Water loss due to a failed valve may occur very quickly or over a long period of time. A fracture may result in a water loss of only a few drops per hour up to the maximum domestic water supply rate of multiple gallons per minute (GPM). The quantity of water released with an open plunger or diaphragm may be up to the maximum design flowrate of the valve; some water solenoid valves tested by Knott Laboratory produce flowrates between 0.7 GPM and 2.0 GPM when fully opened.

Like all plumbing fittings, water solenoid valves work continuously in the background to improve the comfort and convenience of daily life. They manage the water supply to many of our residential appliances and are subject to various failure modes which may result in a water loss condition at any time (i.e., during operation or when idle). The potential for water losses may be mitigated by awareness and control of water chemistry and water pressure or through the use commercially available products intended to cease water flow rates in excess of their designed value.